Vertical: Manufacturing

Application: Improve operational efficiency

Ecosystem: Vodafone

Private Network: 5G

Telecommunications firm Vodafone recently partnered with automotive leader Ford Motor Company to deploy a private 5G standalone (SA) network across Ford’s manufacturing facilities in Valencia, Spain. This dedicated on-site cellular network aims to enable more advanced connectivity and capabilities than were previously possible. Unlike Wi-Fi or public 5G, private 5G offers lowered latency below 10 milliseconds along with improved security and reliability.

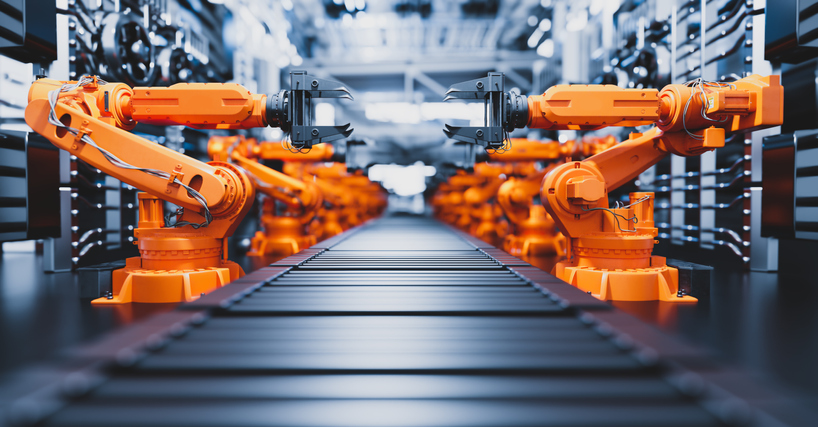

The private 5G network allows Ford to implement innovative new technologies that can instantly adapt to changing conditions on the assembly line. Sensors and machines can also share significantly more data to optimize factory workflows in near real-time. By processing images and videos at the edge of Vodafone’s low latency 5G network, Ford receives rapid feedback on its manufacturing processes. If any issues are detected, the assembly line can be promptly stopped to minimize defective production and material waste.

The advanced connectivity further paves the way for the adoption of augmented reality, virtual reality, and other digital enhancements. Training programs in particular could benefit from more immersive and visual methods enabled by 5G’s high bandwidth and throughput.

By partnering with Vodafone for a cutting-edge private 5G SA deployment, Ford’s manufacturing facilities gain the necessary telecommunications capabilities to match its digital transformation and automation goals. The Valencia project serves as a model for bringing next-generation connectivity to the industrial sector.

The manufacturing sector is the largest user of private networks. Other examples include: